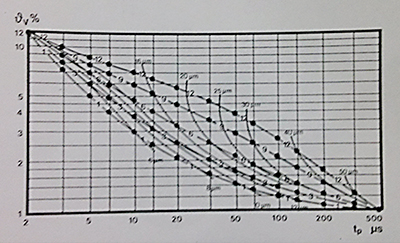

When eroding with ELRO a particulary good surface quality can be achieved during finishing.This advantage considerably lowers the costs of hand finishing (see table of setting parameters)

This result is attained because of the non-porous nature and the uniform,fine grain of the ELRO electrodes(see specification).Because the erosion current is divided up into a number of small channels,sparks with a lower energy content produce shallower and smaller craters and hence a better surface.

2.contour sharpness

For parts with a structured surfance,many corners,or fine,fragile patterns,the edge and corner wear during EDM has a decisive influence on the result which can be achieved.The high wear resistace of ELRO tungsten electrodes is especially important at corrent density rises steeply at such exposed points.

3.Dimersional tolerances and accuracy

As already stated,the lower tendency to thermal distortion of ELRO electrodes-compared with copper-permits a much higher accuracy.This advnatage is especially appreciated when using narrow shapes.

To illustrate the higher removal rate in finishing,the lower degree of wear and better surface quality attainable the table of setting parameters of a leading machinery manufacturer is given.