Characteristics and applications of molybdenum will be summarized in this article.

The density of molybdenum is 10.2 g / cubic centimeters. The melting point and boiling point of molybdenum are 2610 ℃ and 5560 ℃. Molybdenum belongs to a transition element and it is easy to change the oxidation state.

Molybdenum is mainly used in iron and steel industry. Most of molybdenum is directly used to make steel and cast iron as oxidized molybdenum block. Small amount of molybdenum is smelted ferromolybdenum and then is used for steelmaking. In low-alloy steel, the molybdenum content is less than 1%. While, molybdenum in low-alloy accounts for about 50% of the total molybdenum consumption.

Stainless steel can improve the corrosion resistance if adding molybdenum. Cast iron can improve the strength and wear resistance if adding molybdenum. Nickel-base super alloy that containing 18% of molybdenum has high melting point, low density and low thermal expansion coefficient and other properties. This kind of alloy is used in the manufacture of high temperature components in the aerospace. Molybdenum is also widely used in electron tubes, transistors and other electronic devices.

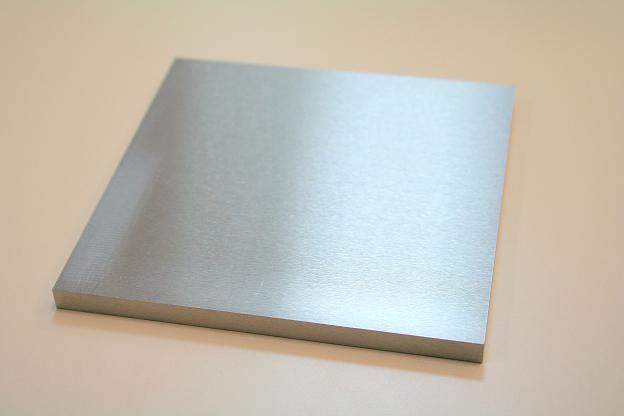

Molybdenum machined products also have a wide range of applications. Pure molybdenum wires can be applied in high temperature furnace electric spark machining and line cutting processing; molybdenum sheet can be used in the manufacture of radio equipment and X - ray equipment; molybdenum crucible is used in rare earth smelting;

In sum, molybdenum can resist high temperature and erosion, so molybdenum is mainly used for manufacturing heat flow orifice, making the gun bore, the rocket nozzle, the filament support of electric bulbs and others.

Tungsten and molybdenum manufacturer-Zhengzhou Sanhui Co., Ltd offers a wide range of tungsten and molybdenum products to you. Let us applying our 24-plus years of rich manufacturing experience to help you.

Contact us today.